NEW TECHNOLOGIES

Professional kitchen: the very soul of the hospitality business

A place where chefs from all over the world practice their creativity but, above all, a place where a feverish work goes on for long hours with an intense production of cooking fumes that may be the cause of olfactory, if not sanitary, ailments.

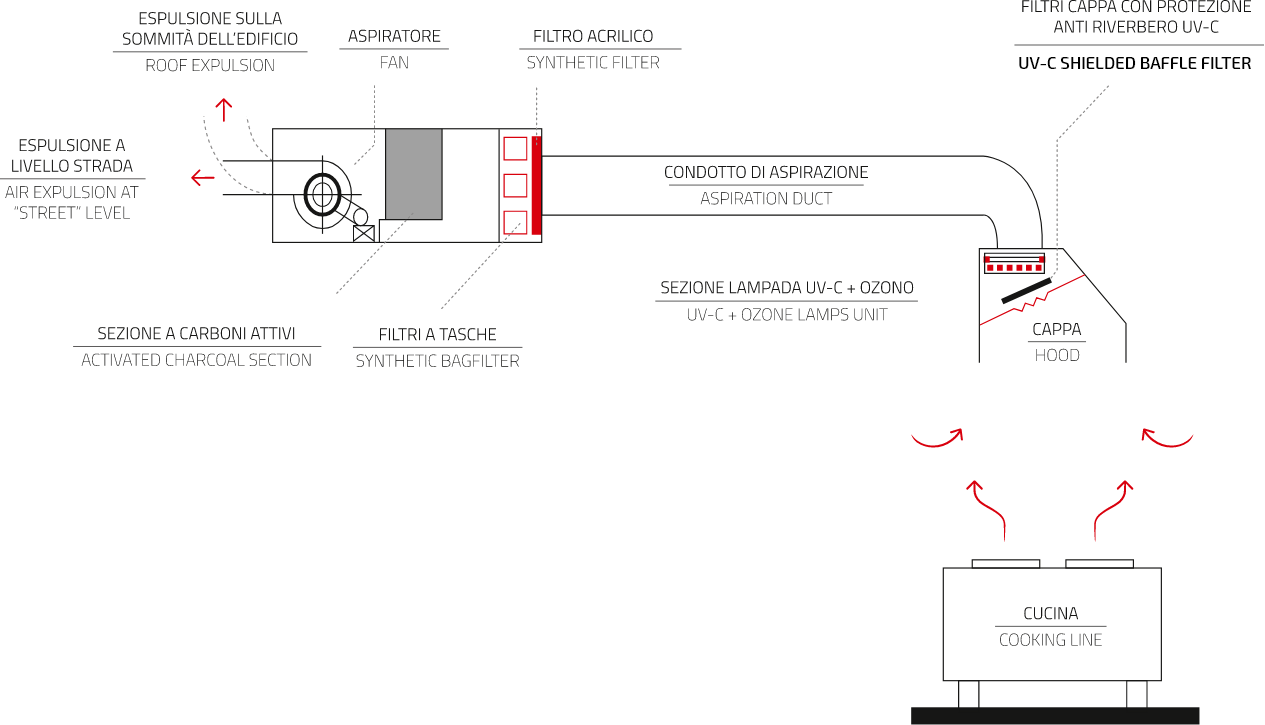

The typical situation that requires an efficient extraction unit and, in most cases, an air filtration system as well.

In fact, whether by using smoke treatments based on UV-C lamps + active ozone (O3), electrostatic filters, vapor condensing units or a combination of them, not only the kitchen/restaurant spaces will benefit of a continuous flow of fresh air but the fumes expelled in the atmosphere will avoid disturbing the people passing by or living in the neighborhood.

UVC+O3

Hygiene, safety, scalability, innovation, quality

hygiene, safety, scalability, innovation, quality

The new Aluminox UVC + Ozone system, installed on simple suction or compensated hoods, is the ideal solution for solving regulatory and environmental problems in the event that a flue is not available up to the top of the roof.

In fact, it allows effective odor neutralization, sanitization of the treated fluid mass as well as the total elimination of grease in the ducts and inside the ventilation motor.

This effect is the result of the irradiation of the fumes with UVC rays which, maintaining the luminosity at the appropriate frequency, act on the treated fluid producing active ozone (O3).

The strongly oxidizing action of ozone combined with the direct effect of UVC radiation, reduces the organic macromolecules produced by cooking food, into simpler molecules that can be expelled without generating odors and pollution.

Depending on the type of cooking and the volume of fumes to be treated, the Aluminox UVC+O3 system can be calibrated to better adapt to every need.

BENEFITS OF THE UVC+O3 TECHNOLOGY

On the maintenance and cleaning of the plant

Traditional hood cleaning is necessary to remove fat and grease deposits inside the fume collection and ventilation systems.

It has to be done at regular intervals, with certain equipment and chemicals, using time and money.

Furthermore, this cleaning involves the use of very aggressive chemical agents which can cause, especially in older ventilation units and ducts, serious problems for the various parts of the system.

The installation of hoods with UVC lamps prevents the deposit of fat and grease inside all the functional parts of the system and, therefore, as maintenance in that case is substantially limited to the replacement of the specific lamps (guaranteed for a duration between 9,000 and 12,000 hours of continuous operation), this technology makes it possible to considerably reduce the maintenance costs of the hoods and associated ventilation systems.

On the health and external environment

By eliminating all fat and grease contained in the cooking fumes, Aluminox UVC+OZONE technology also reduces food cooking odors virtually to zero and kills 90% of all germs, molds and bacteria before the kitchen smoke treated by the collection and transport system is reintroduced into the atmosphere.

This is why it’s use it is appreciated and welcomed by all the local regulatory authorities

On the fire protection

The use of the UVC+Ozone system, due to its main characteristic of preventing the formation of fat and greasy deposits both in the ventilation units and in the flues, reduces the risk of fires and is, for this reason, recommended by all the competent authorities fire protection and prevention.